CIPP for all diameters

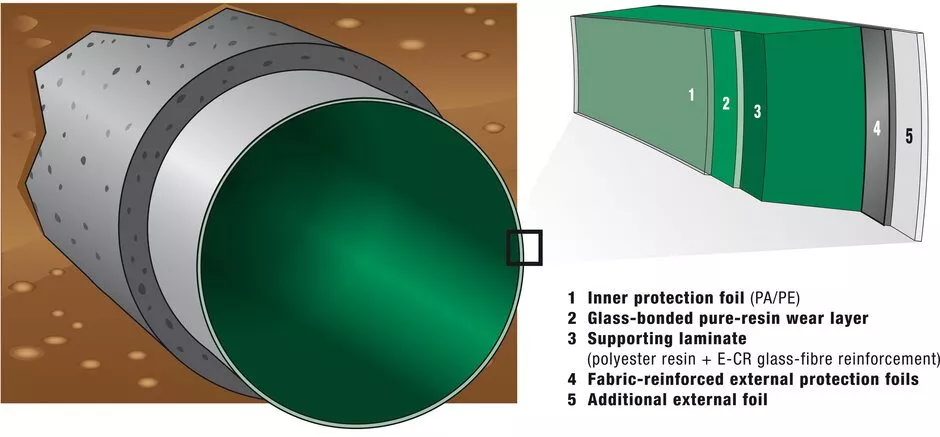

The Brandenburger Liner BB2.5, which is available in all nominal widths, features glass mats with a unique design. This results in a high strength material that meets even the highest static loading requirements and at the same time making it possible to select the thinnest piping hose liner. Brandenburger provides additional external protection, which with its two-layer, fibre-reinforced design protects the liner against any damage before, during and after installation.

In accordance with the modified DIBt certification Z-42.3-490, liners with a DN > 875 have a short-term circumferential elasticity modulus of 16.875 N/mm².

This has been made possible by the redesign of the winding technology on our fourth production line. The new ultramodern plant still uses the winding process by Brandenburger in 1996, for which we still hold a patent, however this process has been refined yet further. This technical progress is also reflected in every further production step; for example, when transporting the film as well as packing away the liners into the transport crates that have been especially designed in-house.

Advantages - Why Brandenburger Liner

The Brandenburger Liner BB2.5, which is available in all nominal widths, features glass mats with a unique design. This results in a high strength material that meets even the highest static loading requirements and at the same time making it possible to select the thinnest piping hose liner. Brandenburger provides additional external protection, which with its two-layer, fibre-reinforced design protects the liner against any damage before, during and after installation.

In accordance with the modified DIBt certification Z-42.3-490, liners with a DN > 875 have a short-term circumferential elasticity modulus of 16.875 N/mm².

This has been made possible by the redesign of the winding technology on our fourth production line. The new ultramodern plant still uses the winding process by Brandenburger in 1996, for which we still hold a patent, however this process has been refined yet further. This technical progress is also reflected in every further production step; for example, when transporting the film as well as packing away the liners into the transport crates that have been especially designed in-house.

The glass-fibre wear protection layer protects the bearing laminate of the liner and simultaneously minimizes the abrasion of the surface. Since the fibre consists of glass, the transparency of the composite is not impaired and the coefficient of expansion remains uniform. Thus the liner holds up to any practical load without disadvantages. The wear according to the Darmstadt abrasion resistance test is less than 0.1 mm and is already included in each BB2.5 additionally to the statically stable wall thickness, without additional costs being charged for it.

The additional external protection provides double protection for the Brandenburger Liner. Liners with large diameters and high weight in particular are additionally protected from mechanical damage during the draw-in process. The double reliability that results from the double-layer external foil composite also means that no closed preliner is necessary when groundwater is present!

The additional external protection also serves as an integrated slide foil, which is also a part of the DIBt certification. This makes it possible in most cases to omit the extra slide foil for the drawing in, which makes it possible to omit a work step at the construction site and thus save costs.

Advantages:

- Double reliability if groundwater is present

- Best protection against mechanical influences

- The slide foil may possibly be omitted

- Reduced efforts during installation and the handling of the slide foil

Brandenburger places a special focus in the development of its products on ease of on-site handling. This provides an added value for the customer with respect to safety and the minimisation of risk during installation, while simultaneously reducing time!

The fibre-laminated external foil bonds the wound laminate with the external foil and can be installed as a compact package. Thus the liner no longer shifts within its packaging during installation.

Due to the special resin recipe of the pipe liner, it becomes very pliable as well as transparent and facilitates the outlining of the lateral inlets. This provides a greater reliability during the subsequent milling open of the inlets.

A further advantage of the special construction can be seen during the preparation of the pipe liner on the construction site. The installation of the light chain also proves to be easy, because the liner remains erect without collapsing right away.

Advantages:

- Easy feeding into the sewer

- Outlining the lateral inlets

- Easy cutting of the material

- Simplified insertion of the light chain

Thanks to the purity of the materials and the special composition of glass, resin and additives, a very high translucency is achieved. This provides the conditions for a reliable and rapid curing of the Brandenburger Liner. As a result, the construction site can be completed speedily, which also saves further costs.